|

As told by Jill Weaver VK6YL -- Part two

The events leading up to Concrete pouring day "C" day

were all explained

in the first part of this saga, now it is "C" day minus one.

At 7.15 PM on Friday night we were informed that the

intended cement

truck had a damaged gear box, the readout for the weigh batching

machine

was needed urgently in the country and just to add to our worries the

front

end loader was required by the Quarry to replace another machine due

for

service. Fortunately a substitute cement truck was arranged and

Peter

VK6PO burnt midnight oil constructing another readout for us to use.

Undaunted we proceeded. Over 20 of us arrived on site

at 8.00 AM,

Saturday the 6th of June (1981), compacted the sand and prepared the

formwork

for the shack floor and roof while all the time the rain clouds

darkened

above. Simultaneously at 10.00 AM the Concrete truck, the

Front

end loader, and the rain arrived. For four hours

ingredients

were weighed, mixed, poured, vibrated and shoveled by the very hard

working

team who thanked the truck driver at 2.00 PM and retired very wet, cold

and soggy for lunch in the quarry shed.

Due to many gallons of water laying on top of the

concrete it was

impossible to trowel it over. It was covered with donated

plastic

and the cleaning up process then began. Meanwhile my OM Bob

(not an Amateur) who had driven the loader all day, continued to ferry

excess blue metal and sand to the hill - filling in potholes on "Tic

Highway"

and leveling out "sump-crushing" rocks until the track became too

slippery

and darkness fell. Around 8.00 PM many very tired but

elated

people wended their weary way home; we had achieved step one of our

goal.

People are wonderful … from several sources we

acquired around 2000

bricks, 1400 new red ones with the balance second hand, which were

transported

to the site in borrowed trailers and cleaned by teams of Amateurs,

wives

and harmonics, who sounded like little elves with their picks and

doonas.

Stan Robson, a bricklayer friend of one of our members volunteered to

build

the shack with our group doing the laboring. Drums and

trestles

were lent by Amateurs, a door frame donated and vent bricks

purchased.

We mixed the cement by hand for Stan who completed the shack in four

working

days and christened it "Ticky". Please note that we call

the

site "Tic Hill". We chose TIC in preference to Tick for

originality.

Much trauma when the day came to lift the roof on top of Ticky …

but with

the aid of a crane - borrowed of course - this was achieved without any

hitches.

Lifting Tic Hill Hut roof

The concrete roof was poured on site on concrete day and

once dry was lifted onto the brick shack. Note the hole for the cables.

Whilst Stan was bricklaying other members were hard

at work removing

the corrugated iron forming which left a beautiful crinkle cut finish

to

the concrete. One of the most back-breaking

jobs

was that of refilling the rocks and gravel around the tower bases and

leveling

off the site. Each week, work continued in an endeavor to

return the area back to a natural contour to allow nature to take her

course

in time to come.

Ilmar VK6ZIB was in charge of the wind generator and

tower which

in no time grew above the trees to 40 feet high. He spent

many

hours of his own time not only on the wind generator and attractively

finished

Zelamite panel housing the controls, fuses etc, but he prepared the

piping

for the co-ax and cables, the bench and many other things - thank you

Ilmar.

Ilmar did most of the wind generator

figuring out and installation

The large wind generator

installed on top of the tower...Will left and Ilmar on right

A moment of contemplation or prayer for

Ilmar...?

Meanwhile other members worked on the 100' antenna

tower.

We

had to pick our days carefully as during winter the rain and winds were

extremely strong - especially for the boys working around the 80' level

of the tower.

One calm Sunday afternoon we ran out of nuts and

bolts.

We were very thrilled when we received a relay from the firm

responsible

for earlier donations to say they would meet us at their business

premises

and give us sufficient to complete the tower.

A tradition was set - hot potatoes at the end of each

working day,

cooked in foil in the coals of the fire originally intended to burn out

a large tree stump. Long after the stump had gone the fire

was lit to provide warmth and a drying agent for the wet and

weary:

Later we enjoyed making a small BBQ from the left over site materials

and

sausages were added to the menu.

We are greatly indebted to the brothers Kevin VK6AKW

and Peter VK6PO

with son Robert for their expertise throughout the project from

beginning

to end, especially with the main tower, liaison with many firms and

hours

of hard work. Peter made a gin pole which allowed us to

lift

the very heavy tower top in place at the 100' level with the 22' 6dB

gain

Co-Linear antenna above this.

Winching up the top section of the main

tower at Tic Hill

Our President Trevor, VK6MS had the unenviable task

of designing

and constructing innumerable items for the site. His

knowledge

and organisation of materials, together with his extensive supply of

tools

never failed to amaze us.

The project would have never eventuated without you

Trevor ......

thank you from all of us.

Above is the original 2

metre 6dB co-linear installed on the top of the main tower for VK6RTH 2

metres. I think this is Martin (no callsign) from Scalar who built and

donated the antenna. This was the antenna that suffered lightning

damage. Note in the picture the batteries and coax (on the large drum)

ready for installation.

The lightning damaged 6dB co-linear which had a lot of water inside. Much barbed wire was run around the entry pipes to

increase security:

later we hope to erect a fence. Lights were fitted inside

Ticky,

which has been painted with several coats of a white water-proofing

solution

on the entire inside and roof top; no mean feat when it was pouring

down

with rain during this process, the solution could only be described as

looking like a soggy flour and water dough … it clung to our

brushes like

glue!

Tic Hill Wind

Generator....There are few photographs.

Will VK6UU, Ilmar VK6ZIB and Barry VK6KBZ continued

working on the

site during the RD contest, taking time off to contact the other

members

participating via the new repeater antennae, wind generator and six

only

2v 500 AH batteries … well done boys! They

discovered that

power line noise was present. Suspecting the 22kV 3-phase

lines

just to the north of the repeater to be the culprit, we set out the

following

Sunday in a 4-wheel drive equipped with foxhunting beam and snoop loops

to track down the offending pole. Murphy showed his

presence

as usual; no power line noise could be heard that day, thought four

very

audibly noisy insulators were located after a spine crunching two hours

almost blazing our own trails in the rocky terrain. The

authorities

have been notified and are going to replace the insulators.

George, the operator of the Catt D988 loader (called

“Betsy”), volunteered

his services with permission of the owners to landscape the terrain

around

our site … we would still be shoveling next Christmas without

his generous

help. Fifty tons of gravel, road base and clay, yuk! Not

too

much clay thank heavens, were carried in the huge bucket and spread

around

the site, with the members shoveling and raking it flat. It

looks lovely, thank you George, for all your work and especially for

our

“pet rock”; all 21 tons of it brought from the quarry to

the site.

Talking of pet rocks, interesting coloured strata was found whilst

jackhammering;

chips of these were sold to boost our very depleted funds.

Spring is now upon us, the wild flowers are in bloom around the area,

and

we hope it will not be long before they return to where we disturbed

the

land.

The repeater has been installed and we are in

readiness for the grand

opening in mid-October. Over 365 day (1 year without

holidays)

working 10 hours each day would have been needed for one man to

complete

the project. There were actually 25 full days (8,760 hours)

worked by the following amateurs, wives, harmonics and friends:-

VK6AD, VK6AUS, VK6AKW, VK6CU, Sue,

VK6EW, VK6FC, VK6HA, VK6HL, VK6KB, VK6KG, VK6KGE, VK6MS,

VK6NWB,

VK6OO, VK6OW, VK6PO, Robert, VK6PQ, VK6RW, Stan Robinson, VK6UO,

VK6UU, VK6YL, Bob, VK6YS, VK6ZBI, VK6ZCK, VK6ZF, VK6ZGA, VK6ZHV,

VK6ZIB,

VK6ZJR, VK6ZKV, VK6ZLT, VK6ZMB, VK6ZBG, VK6ZRE, VK6ZRR, Peter, VK6ZSE,

VK6ZST, Martin, and friend Mark from Scalar.

Many of the Tic Hill construction team

We would like to thank the following, together with

many of our members

list above, for their donations:- Pioneer Quarries, especially George

and

Phil, Cockburn Cement, Swan Portland Cement, Scalar, A and M

Wholesalers,

Ian and Kay More, VK6ABR, VK6EV, VK6IO, VK6NDJ, VK6TO, VK6UN, VK6YE,

VK6ZJS,

with apologies to anyone we have missed. To all those who

purchased

“Pet Rocks”, to members of the WA Repeater Group and all

amateurs and families,

we say thank you for your support.

In conclusion, may I say that it has given me great

pleasure to be

the co-ordinator of this wonderful project … thank you.

This story was published in Amateur Radio Magazine

(August and November

1981).

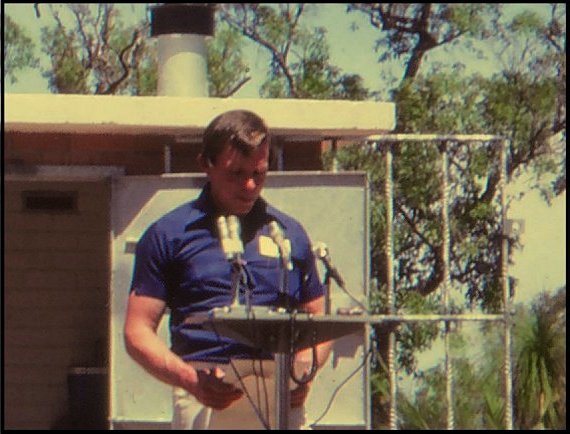

Opening Day

Bruce VK6OO, then VK6 WIA President,

opening Tic Hill, October 1981.

Barry Field VK6BR DOTC (ACMA)

Trevor VK6MS President of WARG

WARG President Trevor VK6MS talking about

the work required for Tic Hill

There were 4 microphones on the dais and at

least one of them must have been recording the opening. I wonder if the

recording still exists...?

More about Opening Day

Opening day of the Tic

Hill, VK6RTH site, was a big well organised day. It was hot and many

people had to be transported to the site for the opening ceremony. The

guest list included the CEO of the ACMA Barry Field VK6BR and the WIA

VK6

President Bruce VK6OO.

Canvas shade was constructed for the large gathering, along with AC

power to run fridges for the cold drinks.

Even though the repeater, VK6RTH 2 metres had been on test from the

site for a number of days, it had been shut down from early morning of

the official opening and was officially "turned on" by a switch on the

dais. As soon as this happened many amateurs checked in to be one of

the first to be on the list of working the repeater.

From memory I think the speakers at the opening were broadcast on

VK6RTH.

|