Tic Hill Repeater Site Photographs

HomeThe photographs are not in any order but I have tried to keep them in some sort of Historical context.

|

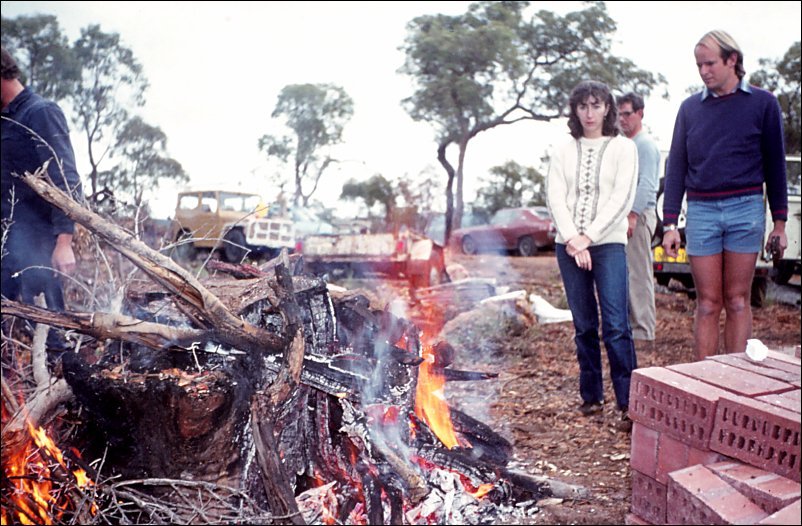

Site

clearing at Tic Hill was all manual labour with little mechanical

advantage used apart from the odd 4 wheel drive to pull a tree out of

the way. All the undergrowth had to be cleared by hand along with a couple of medium size dead trees. The real hard work was to come later when rock and gravel had to be jack hammered out for the large concrete foundations of the wind generator and antenna tower. |

|

First

attempts were made to dig out the rock and gravel for the two tower

foundations but only with limited success. The rock proved just too

difficult to remove without some sort of mechanical advantage. A electric jack hammer was hired for several weekends and it ran almost non stop hammering away at the rock. |

|

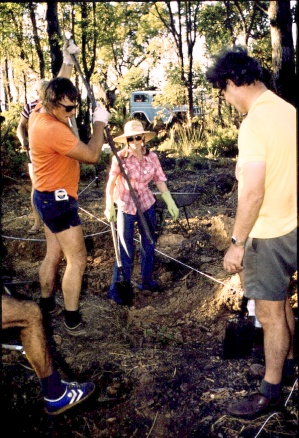

Trevor, Sue and Bill working away on the

rock before the jack hammer was hired. |

|

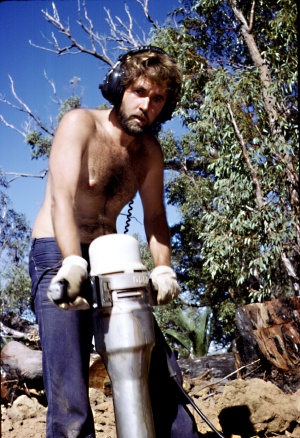

The electric jack hammer that did most of

the rock breaking over several weekends. This is the wind generator foundations with the main antenna tower in the background ready for the concrete. |

|

Owen VK6OW on jack hammer with Phil VK6AD

ready to remove broken up rock. |

|

Will VK6UU doing a stint on the jack hammer

while listening to the WIA news on a Sunday morning. After an hour or

so your hands had a numb feeling and someone else took over. |

|

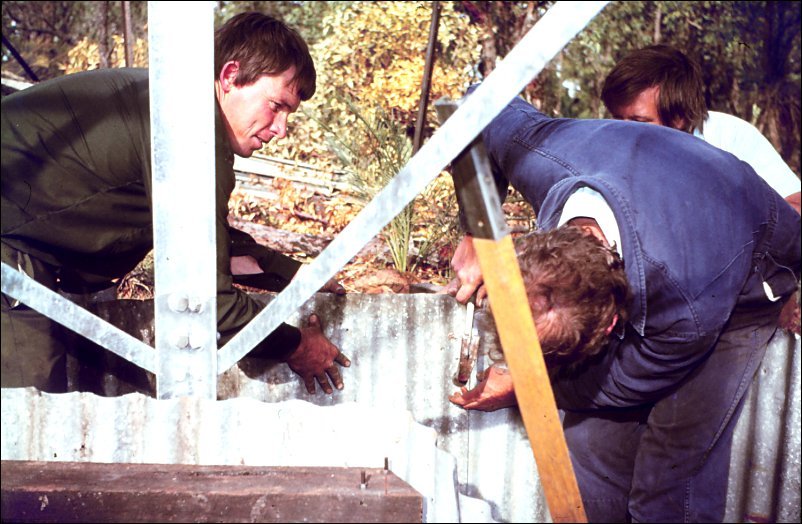

The base of the main antenna tower

pre-assembled ready to tip over into the concrete, once the walls of

the dug out rock had been lined with corrugated iron form work. |

|

Charlie

VK6ZCK bolting together the bottom section of the main tower before it

was tilted into the foundations. |

|

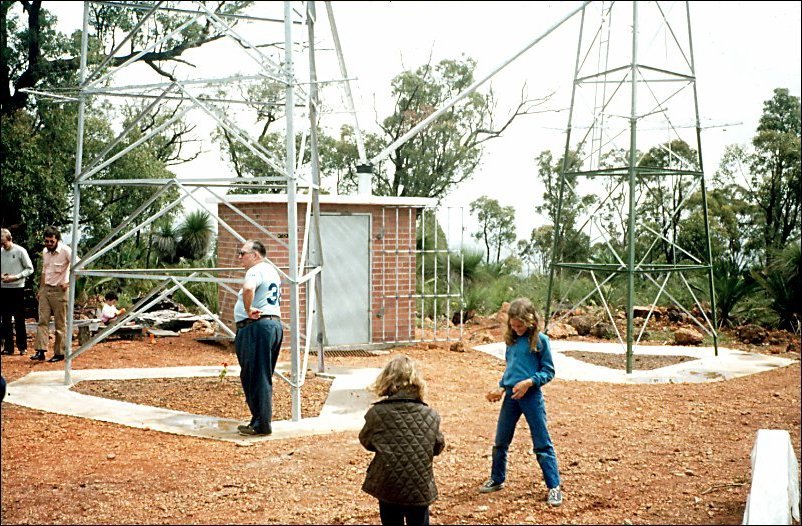

This

photograph shows both tower foundations ready for the concrete pour.

Note the corrugated iron form work. The green tower on the left is the

wind generator tower with the main tower just out of shot to the right. |

|

Concrete

pour day..... The big day arrived to pour the concrete into both tower foundations. The day started fine but towards the end of the day just as the final pours were taking place a large rain front came in and we all got very wet. Note Trevor using a concrete vibrator. This is essential to make sure the concrete moves into all areas and is compacted. Below the concrete stainless steel earth rods were driven into the rock-gravel and then attached to the tower frame. |

|

Concrete

pour day..... The concrete was mixed in the quarry part the way down the hill and transported up to the site. |

|

Concrete

pour day..... Adrian and Sue looking at the finished concrete pour of the main tower. The concrete had to be covered with plastic to reduce damage to the concrete from the heavy rain. |

Even more photographs

Concrete roof poured in the quarry (1 kilometre away) then carried up to the repeater site.

The roof of the hut being positioned for lifting onto hut.

The concrete roof moving into place.

Roof being lowered onto hut.

The workers photograph in the dozer bucket being prepared

And even more Photographs

Wally VK6YS and Owen VK6OW (on the jack hammer.) Wind generator foundations.

Barry VK6Z?? with Adrian VK6CU, Wally VK6YS and Owen VK6OW in background.

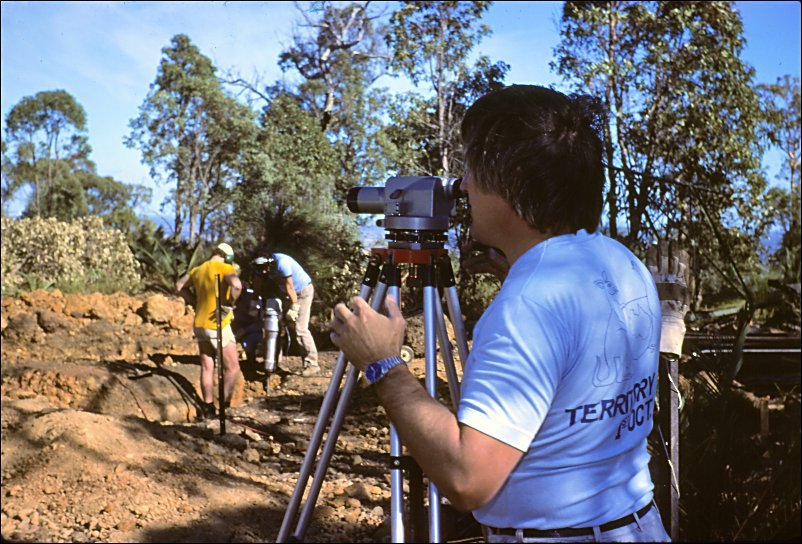

Surveying the site for the tower foundations.

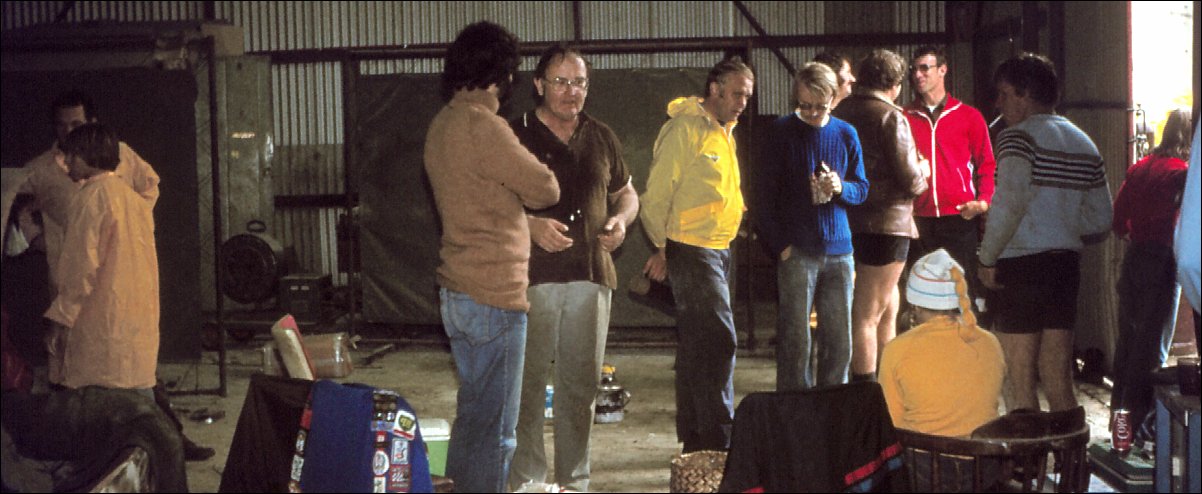

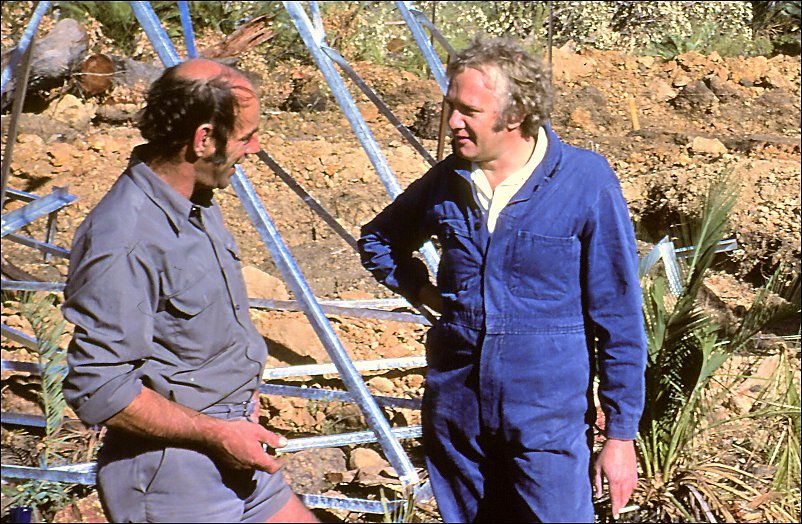

While the women work the guys are talking.

Trevor VK6MS and Phil VK6AD, far right.

Sand for the cement used for the brick work of the hut.

Burning tree bits and keeping warm...Eddie VK6ZSE and Bill VK6KB in the background.

Removing the form work around the concrete.

Chris VK6FC working on the form work.

Adrian VK6CU and Chris VK6FC sorting through the rebar.

Welded on angle iron to anchor tower leg into concrete.

More work on the form work...Trevor VK6MS, Charlie VK6ZCK and Barry VK6Z??

Concrete pour day...Getting dark before the rain....Just made the last pour as the rain started.

Jill VK6YL (SK) working on garden preparations.

Alyn VK6KWN (SK) leaning on tower.

Charlie VK6ZCK on right.

Dave (?) callsign unknown, working on the form work.

After the concrete pour sheltering from the rain at the quarry.